An Ostendo Guide : 6 Core Features to Complement the Growth of Your Business

Many businesses start out by buying accounting software, and then use it to run their operations…keeping inventory control, managing the sales and purchasing orders, billing their customers, collecting payments etc.

However, as businesses grow, the complexity of their operations also grows and there is a need for software that will manage these processes.

Ostendo is one such type of software, integrating with accounting software such as MYOB, Quickbooks, Xero and Sage Pastel. The following is a guide to Ostendo including some of the core features.

Core Features of Ostendo

Inventory in Ostendo

Inventory is the heart of Ostendo. Users set up their stock in 2 main ways – supply from stock (ie the business usually keeps it on hand, and has minimum holding levels and reorder quantities) or source on demand (the business makes it or orders it only when required).

Stock is also set up according to whether it is purchased, assembled or custom – this last will be explained more under assembly as it enables custom bills of materials to be generated on an individual sales line basis.

Inventory in Ostendo can be as complex or as simple as the business requires – Ostendo handles:

- serial number tracking

- colours

- sizes

- warranties

- customer assets (as special type of stock that enables asset servicing)

- stock revisions

- expiry dates

- batch tracking

- pack sizes

- plus length, width and depth

Ostendo also has the ability to set up multiple company warehouses and locations, so that stock quantities and re-ordering can be tracked per site.

Sales in Ostendo

Ostendo has many options available in the sales area. Businesses can set up different sales types for reporting purposes.

- There are counter sales orders, where the stock is picked in the same screen as the sales order (so the assumption is that the person taking the sales order will also pick the order)

- There are delivery sales orders, where sales orders are sent to a completely separate area for picking, packing, dispatching etc.

- The assumption is that a warehouse person will be responsible for filling the order and shipping it. Information about the delivery can be tracked, as well as delivery documents, picking documents and shipping labels being raised

- There are one step orders, where the order is entered and an invoice is raised – the assumption is that the stock has been picked

- There are direct invoices, where there is no sales order entered

- There are recurring invoices, where periodic invoices are raised automatically over a period of time

- There is a Point of Sale, with sales dockets, laybys, workshop, customer pickup and customer delivery

Invoices and sales orders can be customised in virtually any way required by the business.

Jobs in Ostendo

Jobs are a more complex type of sale process than just providing stock. Typically, the three main problems that clients face before using Ostendo are:

- Knowing whether or not the jobs that they are undertaking are actually making a profit.

- Co-ordinating the job. There may be labour and stock components used on a job, there may be a number of tasks to co-ordinate, the jobs may all relate to an ongoing project, there may be progressive invoicing involved, there may be work being done on a customer’s asset, there may be outside businesses involved in doing work for the job and costs to factor into the final profitability

- Ensuring that all work done is invoiced out so that nothing “falls between the cracks”.

By using Ostendo, our clients no longer face these issues.

Some Job Features:

- A job quote or order can be created from a template, and simply amended. Different types of jobs can be created, enabling different functionality as well as reporting. For example a warranty type of job can be created, which automatically is marked as “No Invoice” type job. Other types of jobs can be created to attach work to particular serial number tracked assets (perfect in service type work), etc

- A job quote or order can be made up of a number of different tasks, and each task can have cost elements allocated against it. As the job is built up, the estimated products, labour and other costs can be planned and the overall estimated job profit can be seen on the fly.

In the image below, as each line is added to the job estimate, the top bar reflects the overall job income, costs and anticipated margin and markup. “What if” markup scenarios can be investigated too. On each line, if the costs don’t previously exist in the system, then a planned cost can be entered on the fly.

- When a job is created, a job work sheet can be produced. The work sheet can pull instructions from the template or from the job so that staff know what needs to be done for their particular task/tasks. It can also contain drawings – many clients attach Autocad drawings.

- A job calendar allows tasks to be booked in against staff members (or even machinery) so that the management have a visual overview of the staff activities and work flow. In our own business, our staff are emailed their own calendar each week.

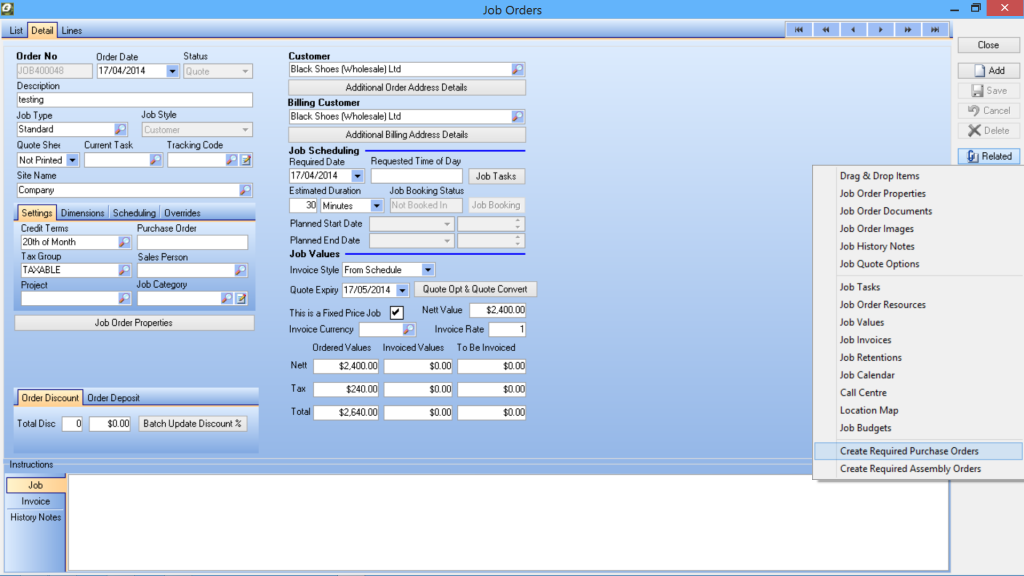

- Within the job, the purchase orders and assembly orders required to fulfil the job can be raised on the fly (see the image below and look to the right hand side where a list of options is shown – Create required purchase orders and Create required assembly orders are displayed)

And since these orders are created from the job, the system links the costs on the purchase orders and assembly orders automatically so that ACTUAL costs and profit can be seen. In fact, the system can track actual costs and profits on a task level, as well as on a job and project level.

Time sheets can be imported, entered manually or even used in conjunction with barcode scanning to track time used against the jobs and determine costs from labour.

- Jobs with any activity against them will automatically appear in Pending Invoices, until the job is completely invoiced out.

- The system also has Job Scheduling which enables the capacity of departments to be set up and then the work load is displayed in relation to the planned schedule.

![]()

Assembly in Ostendo

As would be expected, the assembly process in Ostendo revolves around Bills of Materials, which is the setting up of templates for production of materials, planning costs of labour and materials, the routing sequence (the movement around the stages of production – typically the workflow on the shop floor) and instructions and diagrams for staff to use in order to produce batches of product.

Ostendo deals with a number of complexities in assembly, such as sub-assemblies, phantom assemblies (where the subassembly is used to factor in the components making it up, rather than the finished product – think about a pie, where pastry is the sub assembly..if it is a phantom, the final product would include flour and butter as components rather than pastry) and backflushing (where the system assumes that what was planned as raw materials on an assembly was actually what was used)

In many ways, the Assembly process is like the Job process. Assembly orders are raised and scheduled, with work load being able to be assessed. Work orders are able to be produced, giving the floor staff the complete details of each step of the process. The labour and materials used on the orders are recorded, and management is able to track actual costs against planned costs. However, in Assemblies, the finished product is booked into stock – so even if only part of an assembly order has been produced, it can be booked in so that inventory is kept correct. Wastage is also able to be tracked.

One feature of Ostendo that is particularly good for Custom Manufacturers is the ability to set up an item to be “Custom”. This means that when a sales order is created, there is the ability to create an unique bill of materials for that particular item on the fly. The user would normally access a template of standard labour and materials while entering the sales order, and amend it in light of the customer’s specific requirements or tick a number of options that can be added. Or, with a bit of scripting, a set of questions and answers can be set up for the sales person to run the customer through, and depending on the combination of answers, a unique bill of materials is created from the answers recorded.

Below is an example of a Q&A script that can be used in Sales or Jobs, that will create the unique bill of materials for this particular order:

Service in Ostendo

Ostendo has the ability to create customer assets (or same functionality can be used for company assets). The system also has the ability to set up a service schedule for each asset. There is then a reminder screen where all assets due for a service appear, and an email can be sent out to clients reminding them that a service is due and asking for confirmation. When the client confirms, Ostendo can then generate a job order for the service, linked to the specific customer asset and using a specific job template for that type of service. Once this is done, then all the other features of jobs are available for use.

Because Ostendo keeps the entire history of every transaction, and also easily allows for filtering of lists, technicians can see every service for every asset over the lifetime of Ostendo.

In the screen below, all the service jobs are displayed.

And within a second, the list can be filtered to all the jobs relating to the one asset:

Replenishment Process in Ostendo

The replenishment process is a key element of an ERP system. It enables businesses to keep control of the flow of materials coming in.

It gives businesses the tools to order the right amount of stock, avoiding under and over ordering and avoiding tying cash up in stock that is not required. It means that stock (and other costs) are either bought in or assembled in a timely manner so that sales and jobs are able to be completed by the required date.

Replenishment is used for a particular time horizon – so the business is looking at all the demands for stock or other costs in a fixed time frame, regardless of whether the source is from jobs, sales or assemblies. Ostendo factors in the stock currently on hand, the minimum holdings of the stock, the minimum reorder quantities (or economic reorder quantities), lead times, any forecasts for demand, plus the demand for stock. Taking all these factors into account, Ostendo will then provide a list of suggested stock to order and enable the business to auto- generate purchase and assembly orders.

In the screen shot below, you can see the details of the replenishment calculations for one stock line. It shows the current stock on hand, all the supplies of that stock coming in, all the sources of demand for the stock, the projected stock on hand at end of each day. In the top right of the screen, you can see the reorder basis (minimum stock holding) and the reorder quantities, as well as lead times. These rules then determine the suggested quantity of stock to order in order to get to the correct closing quantity. From this screen, a purchase order will be raised. Of course, the replenishment process isn’t usually done on a one-by-one basis but on all the required stock.

Summary

There are many other features of Ostendo that I haven’t covered in this overview. Just a few are CRM, an inbuilt report writer, custom tables for easy customisation of the system, customisable work flow screens for different users, mobility options for tablets.

Because the product is so feature rich, it is suitable for a huge range of different businesses. It means that businesses don’t need a multitude of databases and excel spreadsheets to run their operations, with all the resultant duplication of entries and possible errors.

Operational users do not need to access the accounting system. With Ostendo ERP, all operational data can be kept in one database and the business can be operated from one system only.